BILSTEIN relies on future-proof plant concept from SMS group

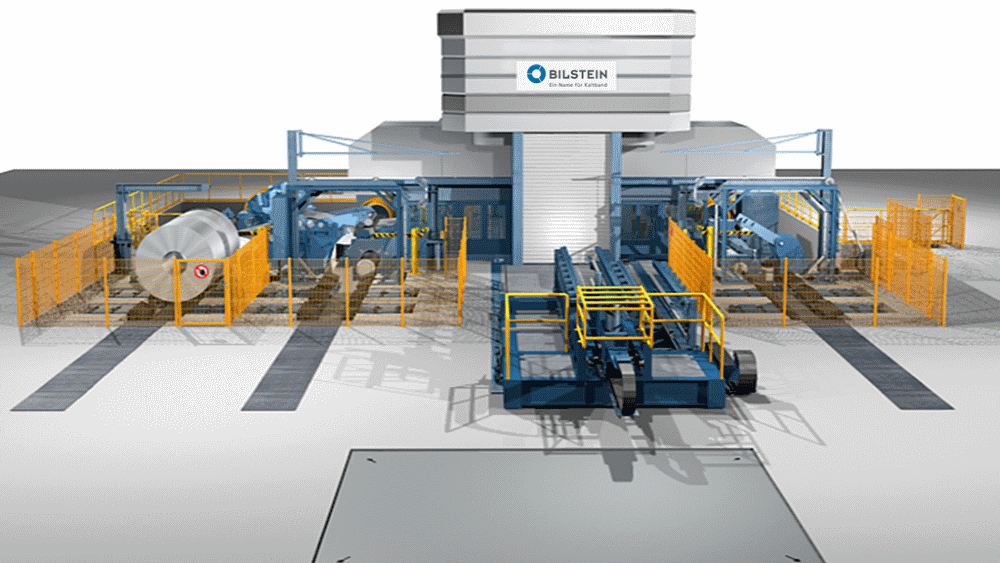

Illustration of the concept for the new combined reversing cold rolling and skin-pass mill for BILSTEIN. © SMS group

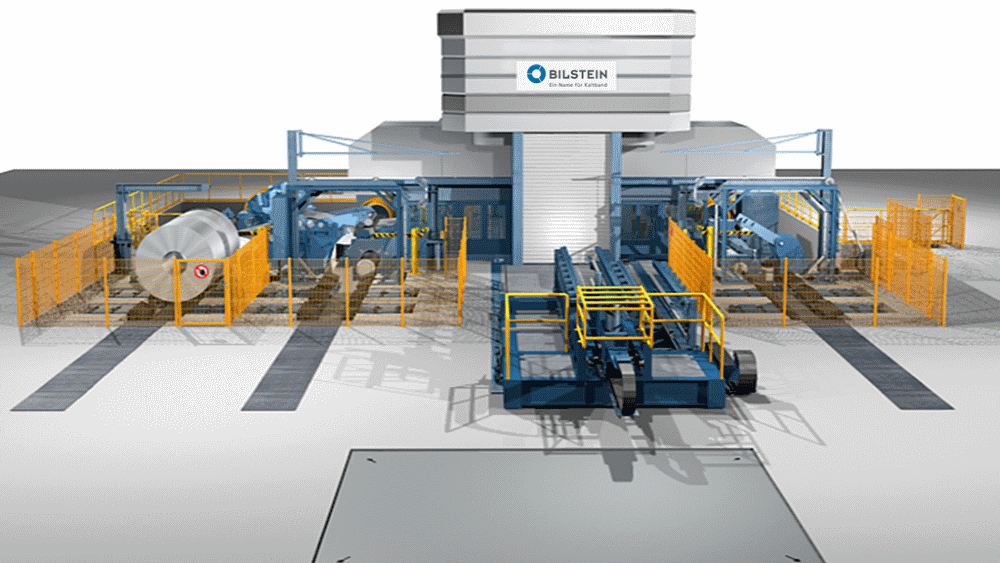

Illustration of the concept for the new combined reversing cold rolling and skin-pass mill for BILSTEIN. © SMS group

On July 25, 2017, BILSTEIN Cold Rolling Mill, parent company of the family-owned BILSTEIN GROUP in Hagen, Germany, awarded SMS group the order to supply a complete four-high reversing cold mill. This high-performance cold rolling mill is designed for reduction and skin-pass (RCM/SPM) operations. The SMS group plant design combines powerful, robust mechanical systems with intelligent, future-oriented process control.

BILSTEIN will receive a high-performance reversing cold mill of the proven CVC® plus design featuring the well-established X-Pact® electrical and automation system. The RCM/SPM is designed to roll and skin-pass a wide range of demanding materials in widths between 600 and 1,350 millimeters and minimal final thicknesses of up to 0.20 millimeters. The plant will be able to roll and skin-pass 290,000 tons of cold strip annually.

In order to achieve the required performance as well as reliable and efficient rolling, the four-high stand will be equipped with small-diameter work rolls. The Sieflex® HT drive spindle, designed to transmit extremely high torques via small-diameter work rolls in order to achieve great pass reductions, even with higher-strength materials, is among the system's many highlights. Another feature of the plant will be the X-Shape flatness measuring and control system, which plays a crucial role in achieving outstanding flatness results.

Special characteristics of the plant include its future-oriented upgradability, allowing, for example, innovative rolling assistance systems to be integrated or the degree of automation to be increased in the future. Process reliability and output will be further enhanced as a result.

Alongside the cold rolling mill and its auxiliary equipment, the peripheral equipment, such as the demineralized water unit, fire extinguishing system, closed cooling water circuit and air treatment systems for balanced shop air management, including preheating and heat recovery, is part of SMS group's scope of supply.

SMS group is also responsible for final erection and commissioning of the new plant. BILSTEIN will benefit from the extensive pre-erection work and tests performed in the SMS group's Hilchenbach facility.

This also includes the full assembly of the mill stands as well as testing of the hydraulic valve stand and the hydraulic positioning system. Only previously tested units will be delivered to the customer. All automation hardware and software will be commissioned in advance in the SMS group test field.

As part of these Plug & Work tests, BILSTEIN's personnel will also receive prior training in the operation of the plant. All these measures will ensure quick and smooth assembly and commissioning and a fast plant startup, and guarantee that BILSTEIN will be able to produce marketable material on the new RCM/SPM from September 2019.

The cooperation between SMS group and BILSTEIN will extend beyond the equipment installation. Both partners aim to establish a long-term partnership based on process-oriented service engineering. The objective of this cooperation is to drive forward the future-oriented systematic refinement of the plant and related processes towards greater system integration.

Performance, process efficiency and sustainability are features characterizing BILSTEIN's new combined reversing cold rolling and skin-pass mill and making it one of the most advanced plants of its kind worldwide.

Source: SMS group