Visitor Registration Opens in May 2026!

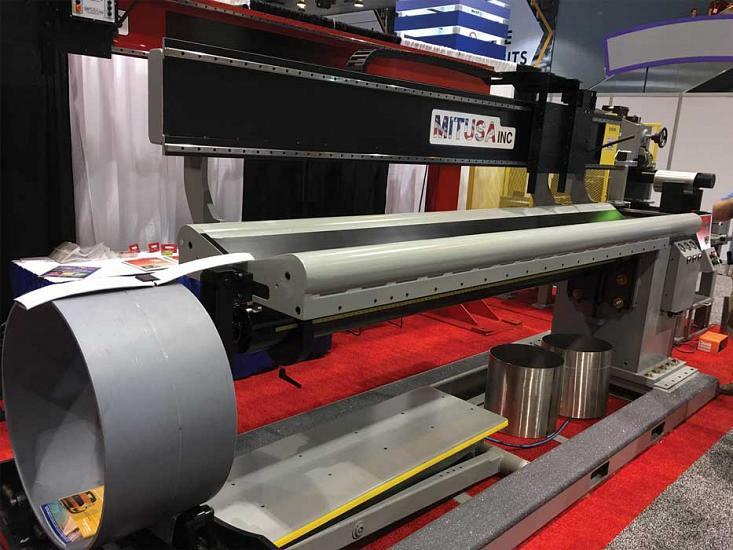

MITUSA Inc. has introduced a seam welding unit that uses linear rails with bearing blocks to move as the seam is made on the tube or pipe. According to the company, this design gives the track a strong hold and allows free travel of the carriage. This additional strength contributes to more accuracy during the welding process and allows the welding power source to be mounted on the carriage.